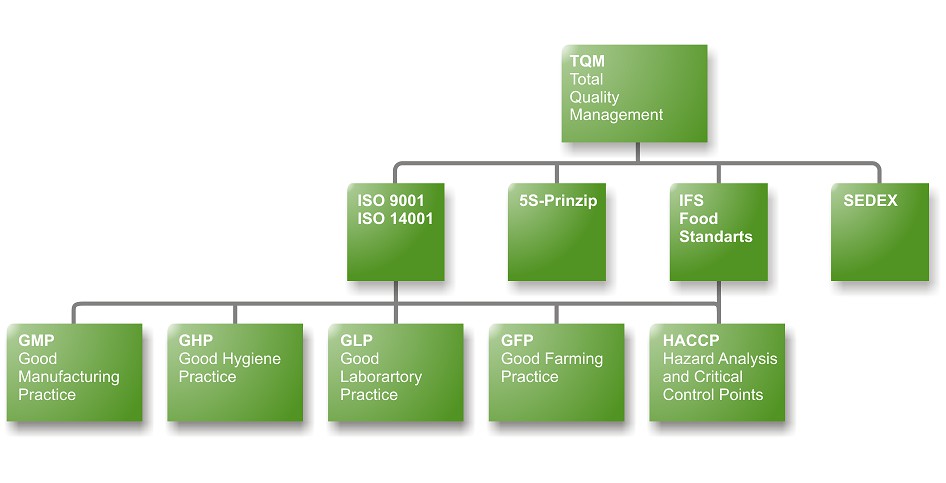

The demand to provide our customers with the highest quality is a matter of course to us. We consequently pursue this goal since the company has been found. The first step was to control the keeping and feeding of animals. Today we work with a complex quality assurance system and have top executives, who implement the necessary measurements in daily business in order to ensure the product quality by each delivery.

The quality management of Delimpex Group incorporates the whole vertically integrated value chain.

The control begins with raw materials, which are necessary for inhouse feed production. Furthermore farming systems are subject to strictest quality regulations, which are completed by quality assurance measurements in the slaughterhouse.

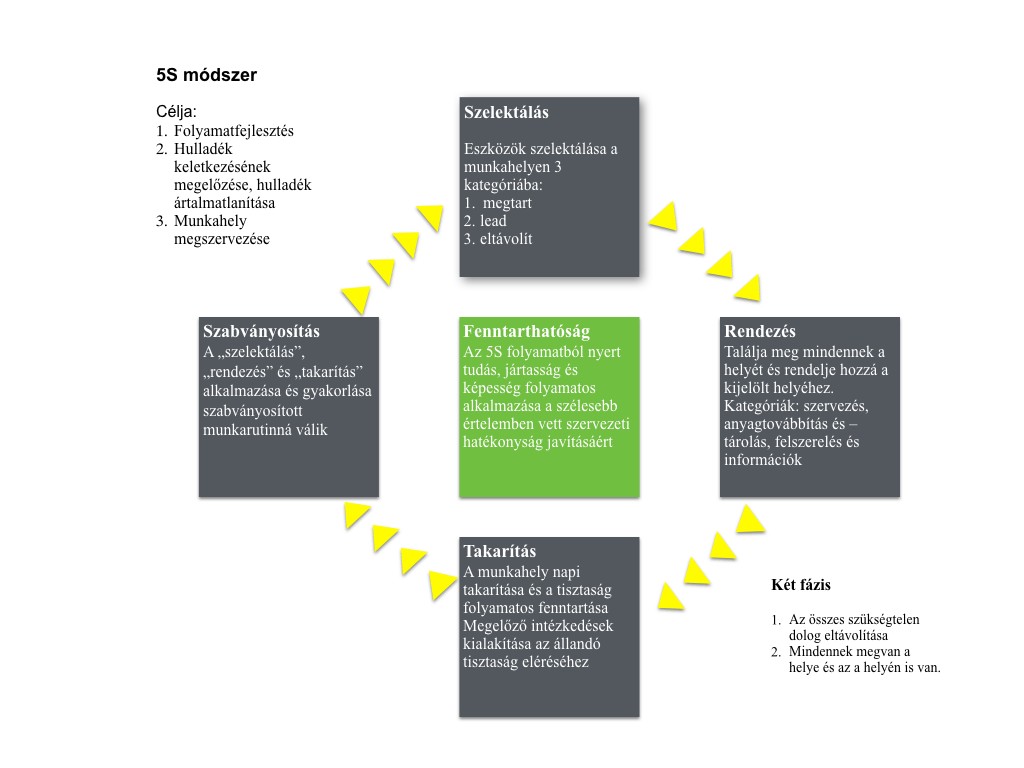

Throughout all value chain stages we follow the principle of 5S, a process development program.

5S method

Work processes are optimized or replaced with the help of this technique. In this context the factors “order and cleanliness” are important. They demonstrate which is truly necessary and how it can be optimally implemented. In the process the steps “Clean and Sort out” follow. The key precondition is standardizing work processes in order to integrate individual process steps into the daily routine and to assure the quality.

The constant high quality of our products is an obligation and a welcome challenge both for our company and for each of our employees. Quality is created by our employees and has to be proved in terms of constant quality every day. Consequently satisfied and well-trained employees are relevant to the success for the company. As a sustainable company we are responsible also for our employees, therefore we have the conditions for our employees checked regularly checked by Sedex. On following link you can find further information about Sedex: http://www.sedexglobal.com/about-sedex/what-we-do/.